|

|

Printing Presses

Printing Presses ?

If your publication requires more than 800 or so copies, it’s almost certainly cheaper to print it on a printing press than it is to reproduce it by photocopying or other means. Printing presses must be prepared for a print job: plate must be done and mounted on the press, so it is not economical for short runs, although the break-even point is changing as presses become more automated.

The Imagesetters

Imagesetters use essentially the same technology as laser printers do, but they print at a much higher resolution on photosensitive paper or film, instead of using toner on plain paper. These films are used by printers (the men, not the hardware) to create the plates that go on the printing press.

How Imagesetters work

There are imagesetters of the flat bed design, capstan imagesetters, and internal and external drum imagesetters. In all of them, exposure takes place with the laser beam, spot by spot across the whole area being exposed. The following illustration describes the functioning of a Capstan Imagesetter. Click to enlarge.

How an Imagesetter works (Pfiffner 1994)

How an Imagesetter works (Pfiffner 1994)[..] the laser beam strikes the

photosensitive paper or film directly. The unexposed film is stored in a

roll in the light-tight supply cassette. It is pulled through the path of

the laser beam by capstan rollers.

(Pfiffner 1994, p. 140)

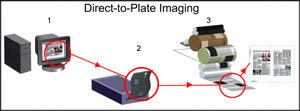

The Direct-to-Plate Imaging

Direct-to-plate imaging cuts out the time and expense of making film negatives by producing the printing plates directly from the digital data, using a device very similar to a laser printer.

In spite of the volume of investment required, it is expected that this technology will be used more and more in the printing companies.

How Direct-to-Plate Imaging Works

The following illustration describes the functioning of a Direct-to-Plate Imaging system. Click to enlarge.

How a Direct to Plate System works, according to (Pfiffner 1994)

How a Direct to Plate System works, according to (Pfiffner 1994)The publication files are produced as

they would be for final film output [1], but instead of being sent to an

imagesetter, they are sent to a digital platemaker [2]. The platemaker works

like a laser printer but uses a special photosensitive plate

material

(Pfiffner 1994, p. 178) to produce printing plates that are ready for mounting

directly on the press [3].

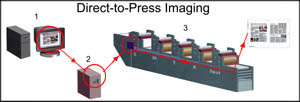

The Direct-to-Press Imaging

In Direct-to-Press Imaging, the plates are produced in-line, inside the press: blank plates are mounted on the press, then imaged in place. The data for the print job is used to generate the printing plate via a direct job process with the appropriate imaging system and plate materials.

How Direct-to-Press Imaging Works

The following illustration describes the functioning of a Direct-to-Press Imaging system. Click to enlarge.

How a Direct to Press System Work , according to (Pfiffner 1994)

How a Direct to Press System Work , according to (Pfiffner 1994) The publication files are prepared for final output [1], and send to the

press computer for the RIP [2], which send the appropriate data to the imaging

head for each colour. Special blank

plates are mounted on the press, and then the imaging heads burn the page

onto the plate

(Pfiffner 1994, p. p178)[3].